In the production of sand and gravel aggregates, raw materials typically undergo three to four stages of crushing and shaping to achieve the desired particle size. Each stage demands specific crushing equipment tailored to the material’s properties and production goals. At Dainamu, headquartered in China, we provide cutting-edge crushing solutions to optimize these processes. This content delves into the nuances of choosing the appropriate crusher for each crushing stage, ensuring efficiency and quality in aggregate production.

Table of Contents

- 1. Primary Crushing (Coarse Crushing)

- 2. Secondary and Tertiary Crushing (Medium and Fine Crushing)

- 3. Sand Making and Shaping Stage

- 4. Conclusion: Optimizing Crusher Selection

- 5. Contact Dainamu

1. Primary Crushing (Coarse Crushing)

Primary crushing, often referred to as coarse crushing, is the first step in breaking down large raw materials into smaller, manageable sizes. This stage is essential for preparing materials for subsequent processing. Typically, the input size ranges from 500 to 1500 mm, with the output size reduced to 100 to 350 mm, depending on the equipment and production requirements.

Input and Output Sizes for Primary Crushing:

- Input: 500 - 1500 mm

- Output: 100 - 350 mm

1.1 Commonly Used Crushers for Primary Crushing

For primary crushing, the most widely utilized equipment includes jaw crushers and gyratory crushers. These machines are designed to handle the initial reduction of large, tough materials efficiently.

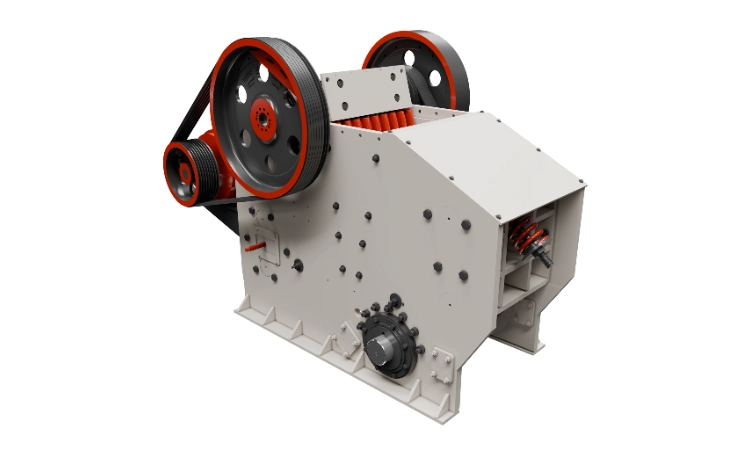

Jaw Crusher:

Jaw crushers are among the earliest forms of crushing equipment, valued for their straightforward design, reliability, and ease of maintenance. They are extensively used across industries such as metallurgy, chemical processing, building materials, and power generation. Jaw crushers operate by compressing materials between two jaw plates, making them highly effective for crushing hard substances like granite. Their versatility and low operational costs make them a staple in primary crushing applications.

Gyratory Crusher:

Gyratory crushers, sometimes referred to as vertical compound crushers, excel in high-efficiency coarse crushing. They are characterized by their ability to process large feed sizes, simple production processes, and minimal maintenance needs. These crushers are particularly advantageous in large-scale mining operations, where they handle relatively hard materials with ease, delivering consistent performance and high throughput.

1.2 Differences Between Jaw and Gyratory Crushers

While both jaw and gyratory crushers serve primary crushing purposes, their differences in design and functionality cater to distinct operational needs. Below is a detailed comparison:

- Suitable Materials and Applications:

- Jaw Crusher: Capable of processing ores with high moisture and viscosity without clogging, jaw crushers are ideal for smaller quarries and mineral processing plants seeking reliable primary crushing solutions.

- Gyratory Crusher: Effective across a range of material hardness levels but less suited for viscous ores. They are commonly deployed in large-scale mineral processing facilities requiring robust, continuous operation.

- Production Capacity:

- Gyratory Crusher: Offers continuous crushing with high output and a significant crushing ratio, ensuring stable and efficient performance for high-volume production.

- Jaw Crusher: Operates intermittently, resulting in lower crushing efficiency compared to gyratory crushers, though still sufficient for many applications.

- Design and Structure:

- Jaw Crusher: Features a simple, compact design with low production costs and a smaller machine height, facilitating easy maintenance and installation.

- Gyratory Crusher: More complex and taller, with a larger footprint that demands substantial infrastructure investment and limits portability.

- Feed and Discharge Sizes:

- Jaw Crusher: Has stricter feed size requirements, often necessitating pre-blasting of oversized rocks. The output tends to include more needle-shaped particles.

- Gyratory Crusher: Accepts larger feed sizes and produces smaller, more uniform discharge particles with fewer needle-shaped fragments, enhancing downstream processing.

- Maintenance and Costs:

- Jaw Crusher: Lower initial investment but higher wear on jaw plates due to its compression-based crushing, requiring more frequent replacements.

- Gyratory Crusher: Higher upfront cost but employs a layered crushing principle, extending the lifespan of wear parts and reducing maintenance intervals.

Key Takeaway for Primary Crushing: Gyratory crushers are preferred in large-scale mineral processing plants for their high capacity and crushing ratio, except when handling viscous materials. Jaw crushers are suitable for smaller operations or when a single unit meets production demands. For a deeper dive into these options, explore our comparison of jaw and gyratory crushers.

2. Secondary and Tertiary Crushing (Medium and Fine Crushing)

Secondary and tertiary crushing stages, often termed medium and fine crushing, follow primary crushing to further reduce material size. Secondary crushing typically processes materials from 350-100 mm to 100-40 mm, while tertiary crushing refines them to 30-10 mm, depending on the desired output.

Input and Output Sizes:

- Secondary Crushing: Input: 350-100 mm, Output: 100-40 mm

- Tertiary Crushing: Input: 100-40 mm, Output: 30-10 mm

2.1 Commonly Used Crushers for Secondary and Tertiary Crushing

Cone crushers and impact crushers are the primary equipment choices for these stages, with fine jaw crushers gaining traction for their cost-effectiveness in certain scenarios.

Cone Crusher:

Cone crushers are designed to handle medium to hard rocks and ores, such as granite and river pebbles. Dainamu offers a range of cone crusher variants, including spring cone crushers, Simmons cone crushers, compound cone crushers, single-cylinder hydraulic cone crushers, and multi-cylinder hydraulic cone crushers. This variety allows customers to select the best fit for their specific needs, ensuring optimal performance in secondary and tertiary crushing.

Impact Crusher:

Impact crushers utilize impact energy to break materials, making them suitable for brittle substances of medium hardness or lower. They produce cubic-shaped particles, offering high efficiency, a substantial crushing ratio, and a compact design. These characteristics make them valuable for applications requiring well-shaped aggregates.

2.2 Differences Between Cone and Impact Crushers

Both cone and impact crushers are effective for secondary and tertiary crushing, but their differences influence their suitability for specific tasks:

- Application Scope:

- Cone Crusher: Excels at crushing hard materials like granite, basalt, tuff, and river pebbles, making it a go-to choice for demanding applications.

- Impact Crusher: Best suited for less hard, brittle materials such as limestone, commonly used in construction and recycling projects.

- Discharge Size:

- Cone Crusher: Produces smaller particles, ideal for mineral processing projects requiring fine outputs.

- Impact Crusher: Yields slightly larger particles, often used in construction and building material production.

- Finished Product Shape:

- Impact Crusher: Delivers superior cubic shapes with fewer edges, enhancing aggregate quality.

- Cone Crusher: May produce more needle-shaped particles, potentially requiring additional shaping for certain applications.

- Production Capacity:

- Cone Crusher: Provides low energy consumption, high output, and consistent performance, making it suitable for large-scale production lines.

- Impact Crusher: Offers high crushing efficiency and ease of maintenance, ideal for high-quality road construction and concrete recycling.

- Cost Considerations:

- Cone Crusher: Higher initial cost but lower long-term maintenance due to durable wear parts.

- Impact Crusher: Lower upfront cost but higher maintenance expenses from frequent wear part replacements.

Key Takeaway for Secondary and Tertiary Crushing: Cone crushers are optimal for large-scale stone production lines handling harder materials, while impact crushers suit smaller lines or projects prioritizing particle shape. For strict shape requirements, combining a cone crusher with an impact crusher or sand-making machine is effective. Learn more in our insights on choosing cost-effective crushers.

3. Sand Making and Shaping Stage

When the material size or shape from prior stages doesn’t meet requirements, a sand-making machine, such as a Vertical Shaft Impact (VSI) crusher, can refine and shape it further. This stage is critical for producing high-quality sand for various applications.

3.1 Vertical Shaft Impact (VSI) Crusher for Sand Making

The VSI crusher, also known as a sand-making machine, is widely employed for producing and shaping sand from materials like limestone, river pebbles, granite, and ore tailings. It supplies premium aggregates for highways, high-rise buildings, municipal projects, stone plants, hydroelectric dam construction, and concrete mixing stations. Typically, the input size is less than 40 mm, with an output of 0-10 mm.

Input and Output Sizes:

- Input: Less than 40 mm

- Output: 0 - 10 mm

With growing demand for sand and gravel aggregates and restrictions on river sand extraction, Dainamu’s VSI crushers from China are increasingly vital for efficient sand production lines.

3.2 Advantages of VSI Crushers

VSI crushers provide numerous benefits, making them a cornerstone of modern sand production:

- Superior Sand Shape: Produces cubic-shaped sand with low needle-like content and adjustable fineness modulus, meeting high-quality standards.

- Easy Maintenance: Features a hydraulic lid-opening device, simplifying inspection and maintenance of the crushing chamber, saving time and effort.

- Oil Lubrication System: Includes a thin oil lubrication station that ensures optimal bearing performance, extending equipment life and reducing manual maintenance.

- Flexible Feeding Methods: Supports switching between full central feeding and central feeding with cascade feeding, as well as “rock-on-rock” and “rock-on-iron” crushing modes, adapting to diverse needs.

- Low Environmental Impact: An air circulation system reduces dust emissions, minimizing environmental pollution and enhancing site sustainability.

These advantages position VSI crushers as essential tools for producing consistent, high-quality sand efficiently.

4. Conclusion: Optimizing Crusher Selection

Choosing the right crusher for each crushing stage involves evaluating material hardness, feed and discharge sizes, production capacity, investment costs, and desired particle shape. Dainamu recommends the following approach:

- Primary Crushing: Opt for jaw crushers in smaller operations or with viscous materials; use gyratory crushers for large-scale, high-capacity needs.

- Secondary and Tertiary Crushing: Select cone crushers for hard materials in large production lines; choose impact crushers for better particle shape in construction applications.

- Sand Making: Employ VSI crushers to produce premium sand with excellent shape and gradation.

By aligning crusher characteristics with your project’s specific demands, you can maximize efficiency, reduce costs, and ensure top-quality output. For tailored advice, reach out to Dainamu’s experts.

5. Contact Dainamu

For further details on our crushing solutions or to discuss your project, contact us at anhuisiluoman@gmail.com or visit Dainamu’s website. Based in China, Dainamu is dedicated to delivering advanced, reliable equipment for your crushing and screening needs.